Timothy

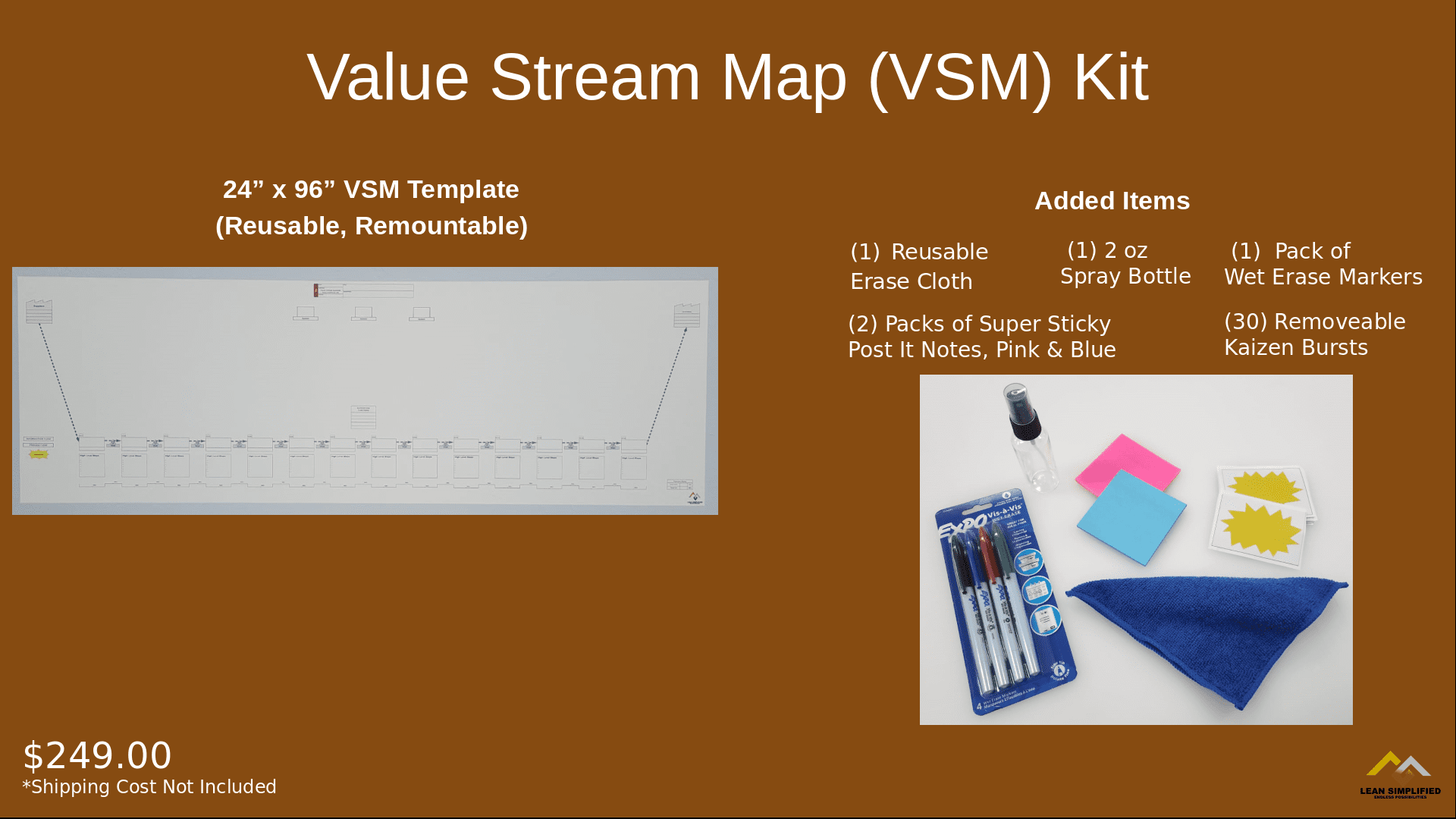

Experienced executive with a demonstrated history of working “hands on” in the manufacturing & supply chain industries. Lean-focused leader with decades of experience leveraging a “Learn / Do” philosophy to drive initiatives across matrixed organizations. Charismatic communicator skilled at exposing hidden wastes while building relationships at all levels. Forward thinking in helping companies transition to a new future state while conducting training with practical application on the Gemba (Shop Floor, Lean Assessment/certifications, Value Stream Mapping- both within the four walls as well as the Extended Customer VSM Joint Sessions)

Timothy

Timothy Sroka is the Founder and CEO of Lean Legacy 2020 – focused on Lean consulting with numerous companies in the startup or deploying of Lean at any level or industry. The focus is on helping organizations implement Lean principles and methodologies to improve their processes, reduce waste, and enhance overall efficiency. The success factor for Tim is that he has the unique ability to make connections (relationship building) very quickly while embracing the current state of the companies he works with to deploy continuous improvements focused on the Customer while changing the “language and actions that will lead to a very successful future state.

Lean-focused leader with 40+ years of cross-industry experience driving impactful initiatives across multiple disciplines.

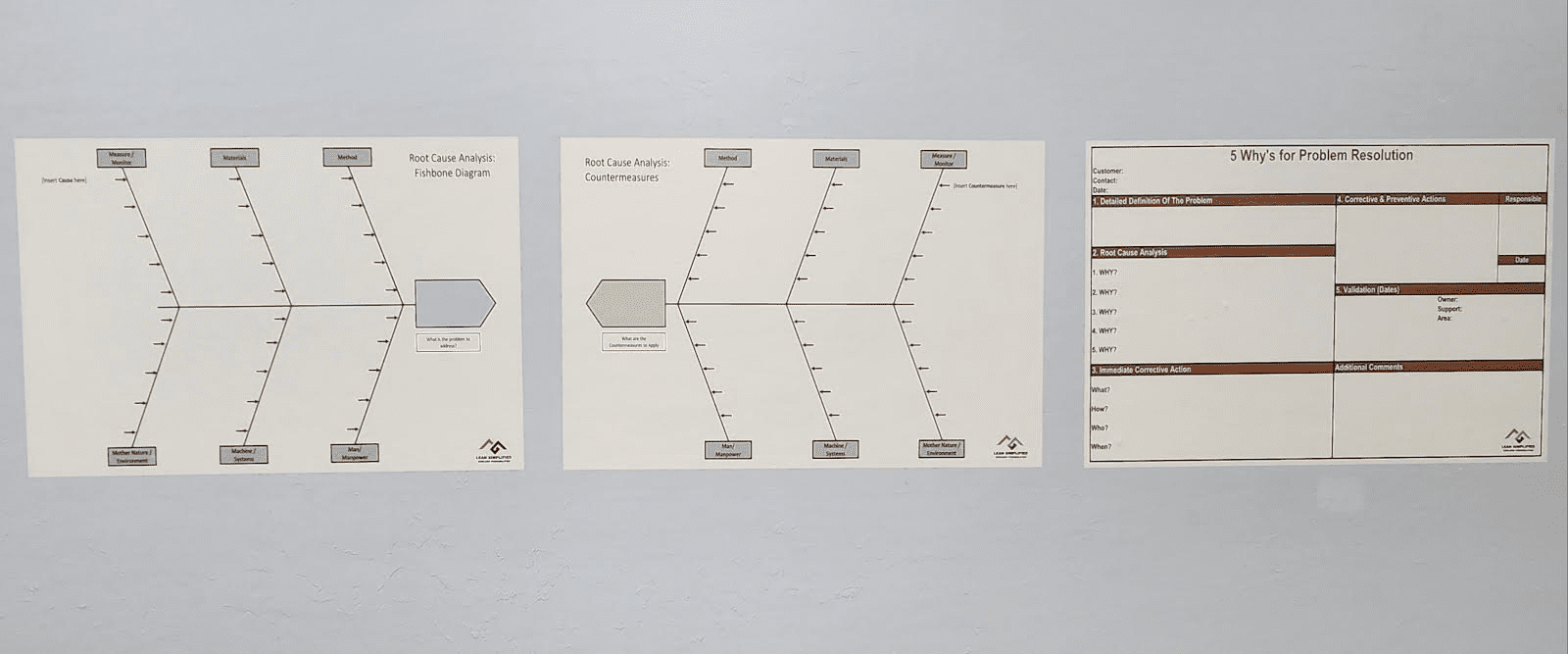

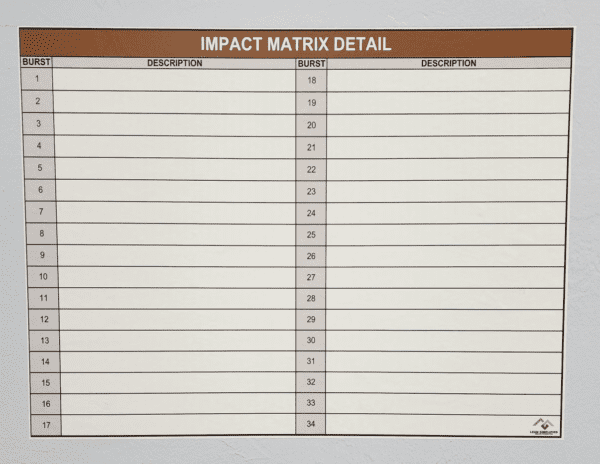

Deep Knowledge of Lean Principles with thorough understanding of Lean principles, including concepts such as value stream mapping, waste reduction, continuous improvement, problem solving skills and customer-centricity.

Articulate communicator skilled in strengthening relationships with direct reports, peers and senior leadership. Drives change with high energy and “can do” attitude that brings out the best in the people that he works with.

Proven mentor, trainer, and director of multidisciplinary teams in line with aggressive performance metrics.

Experienced with change management strategies and skilled at managing resistance to change. He is patient, persistent, and committed to the long-term success.

Tim is an experienced executive with a demonstrated history of working “hands on” in the manufacturing & supply chain industries. Lean-focused leader with decades of experience leveraging a “Learn / Do” philosophy to drive initiatives across matrixed organizations. Charismatic communicator skilled at exposing hidden wastes while building relationships at all levels. Forward thinking in helping companies transition to a new future state while conducting training with practical application on the Gemba (Shop Floor, Lean Assessment/certifications, Problem solving, Value Stream Mapping- both within the four walls as well as the Extended Customer VSM Joint Sessions)

The Lean principles and methodologies have been deployed in various settings and industries

Manufacturing

Applied in manufacturing by promoting a culture of continuous improvement and involving all employees in identifying and eliminating waste in processes. Use a friendly and inclusive approach to encourage employees to voice their suggestions and concerns.

Service Industries

Applied in service industries such as banking, insurance, and hospitality. Looked at ways to transform and re energize while thinking “out of the box” with so many opportunities exposed

Supply Chain Management

In the supply chain, helping to optimize inventory management, reduce lead times, and improve overall efficiency. Foster collaboration among suppliers, manufacturers, and distributors while maintaining a friendly and respectful relationship.

Startups and Small Businesses

Deep dive into the details to operate efficiently with limited resources. Encourage a culture of adaptability, where employees feel comfortable suggesting improvements and experimenting with new ideas.

In all these settings, the key is to create an environment where people feel comfortable sharing their ideas, concerns, and feedback. A friendly voice, open communication, and a commitment to continuous improvement are essential elements of successful Lean deployments. Tim is the change agent needed to inspire, motivate and bring the optimistic opportunities to transform companies as well as individuals at any levels in the Lean journey.